Moulded Composites

One of the key areas of expertise we have here at Polar Technology is in the development of moulded composite products. We have utilised this method to create a wide spectrum of composite structures and components, including class-A surface components for hyper cars, the bike frames for Team GB at the 2016 Rio Olympics and bladed fans for aerospace propellers.

Our Capabilities

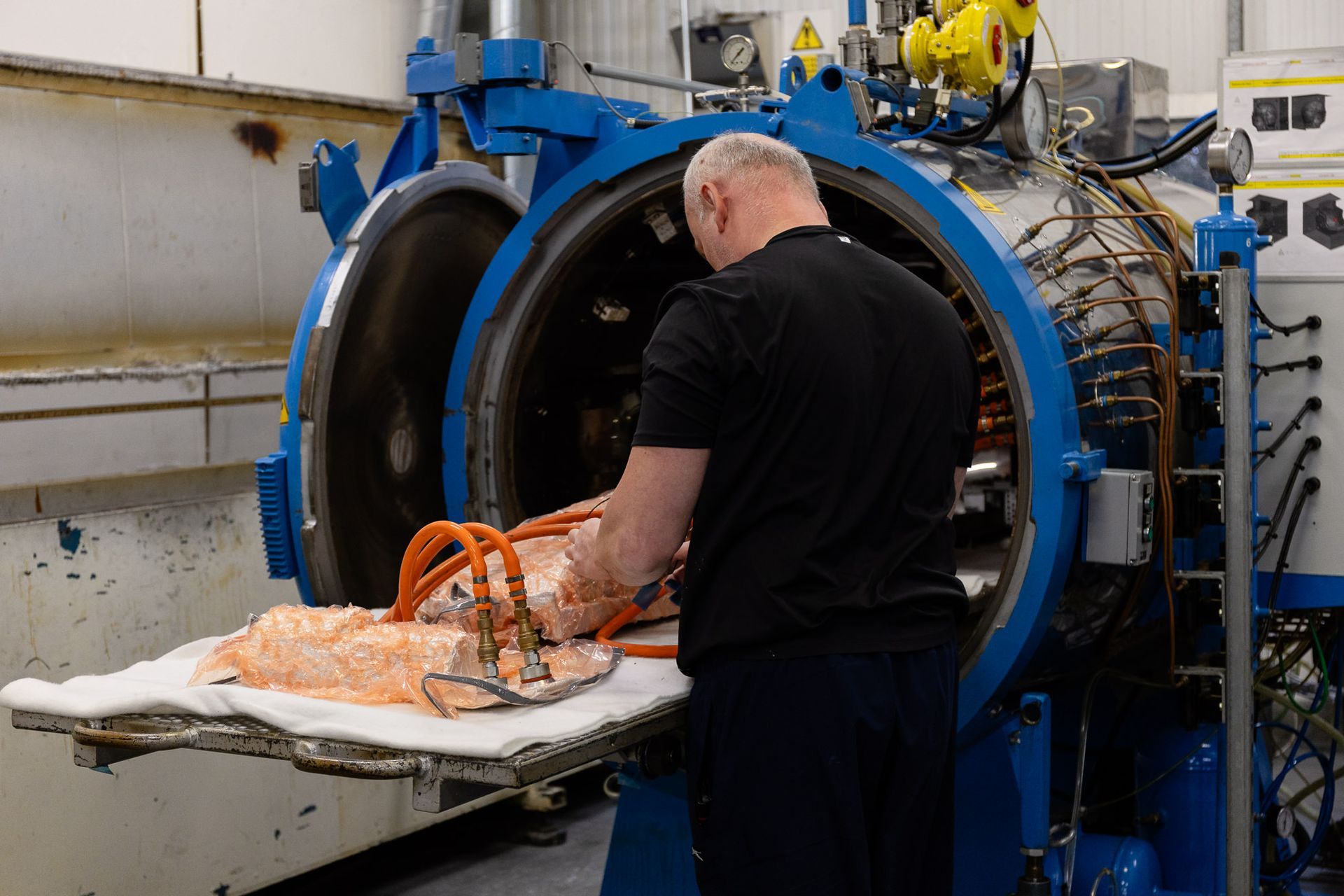

Autoclaves

We have four on-site autoclaves and several configurations of ovens, suitable for curing wet and pre-preg products.

Cutting

Using our CNC machining centres, we can create clean and precise patterns without any damage or distortion to the material.

Resin Transfer Moulding

Resin Transfer Moulding (RTM) uses a closed mould with a dry fibre preform, where a liquid resin is injected and cured inside the mould.

Laminating

Our skilled laminating team can support with a variety of complex, high-volume projects.

Machining

Our facilities include single and twin spindle machines for turning composite components plus comprehensive 3,4 and 5-axis milling machines.

Assembly

We offer our customers mechanical and electrical assembly, as well as full supply chain management and lineside and kanban delivery.

Paint Shop

Our specialist, in-house paint shop can provide a variety of high-spec finishes for visual products

Autoclaves

We have four on-site autoclaves and several configurations of ovens, suitable for curing wet and pre-preg products.

Cutting

Using our CNC machining centres, we can create clean and precise patterns without any damage or distortion to the material.

Insights

Relevant Products

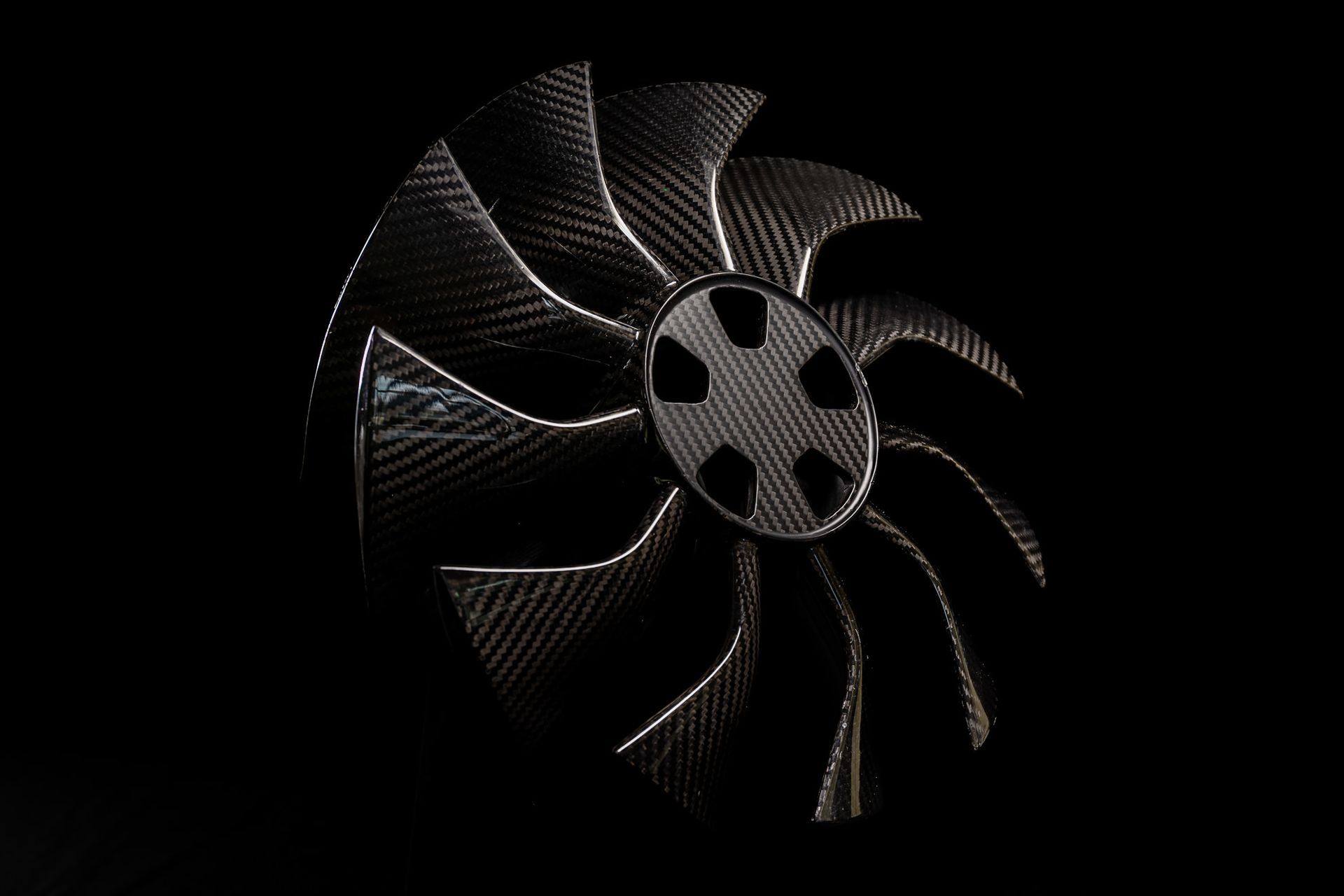

Composite Blades and Fans

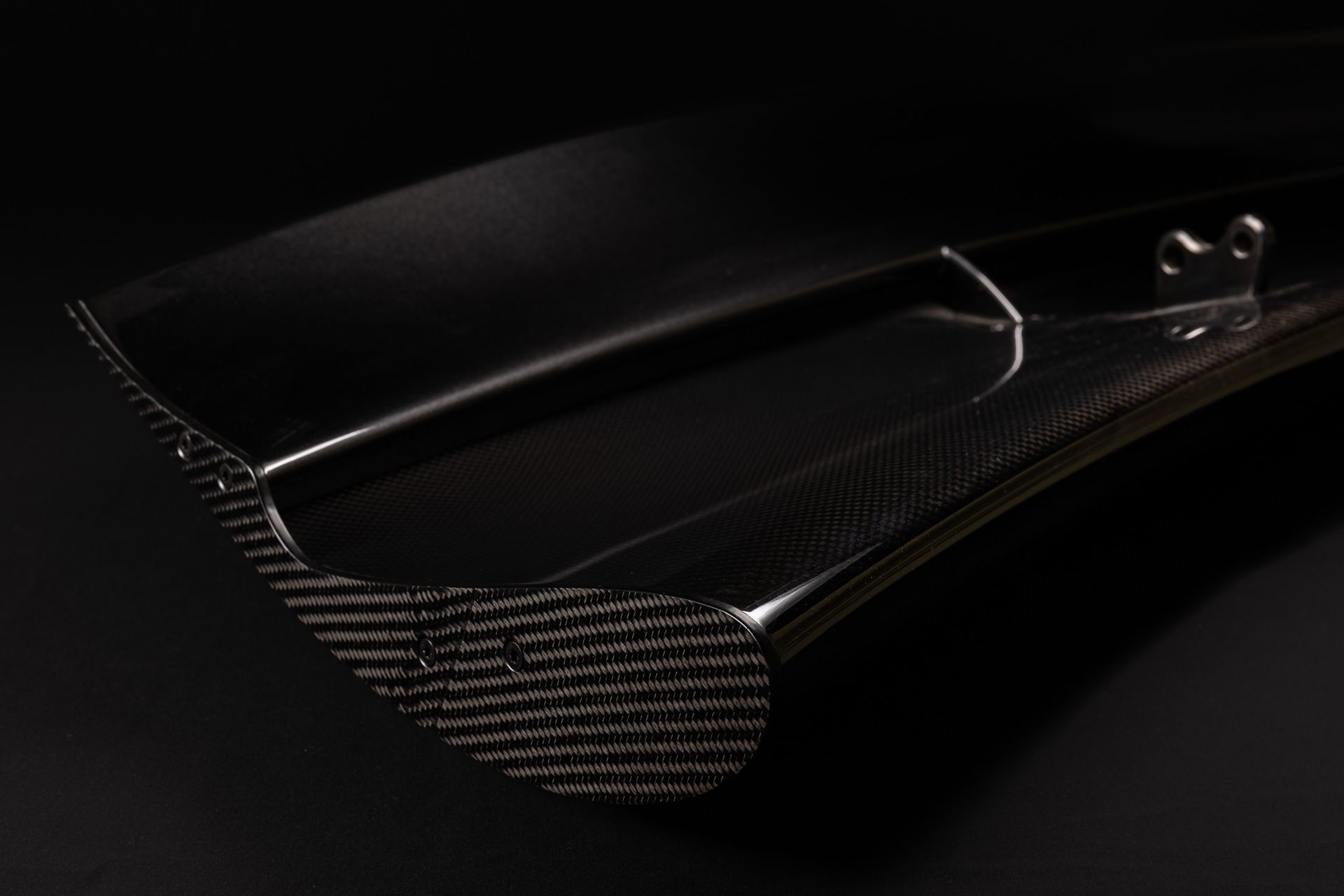

Find out moreActive Aerodynamic Structures

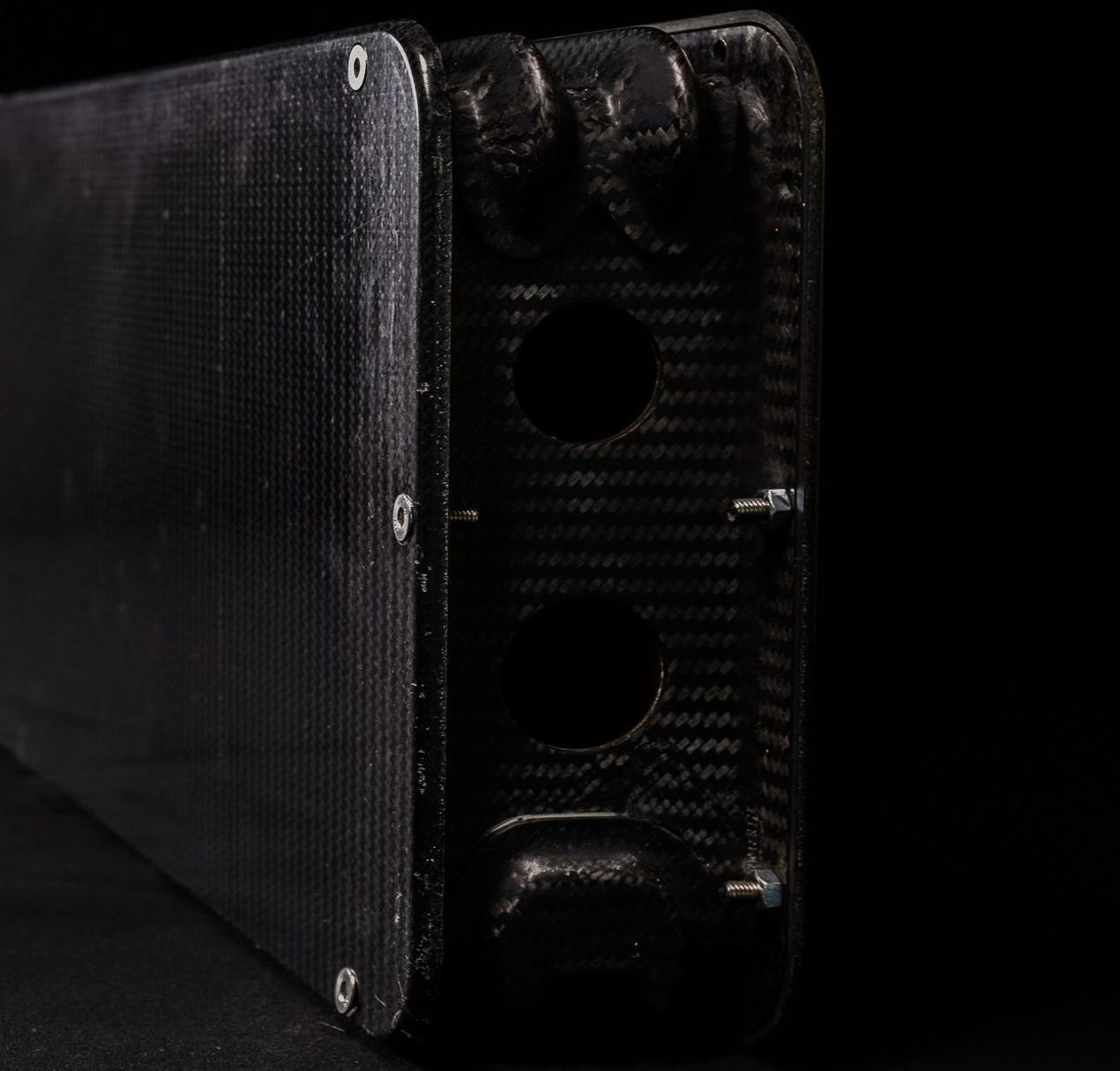

Find out moreBattery Enclosures

Find out moreComposite Gears

Find out moreVisit us:

Horizon Technology Park, Stanton Harcourt Rd, Eynsham OX29 4GF

| Polar Technology Management Group Ltd

Website Design by Warpspeed Web