Fabrication & Additive Manufacturing

We are leading specialists in the design and manufacture of bespoke, advanced precision fabrications and thermal management systems for high tech industries. Products are used in harsh environments where extreme temperatures, highly corrosive conditions and severe vibration loads are experienced.

Our offerings include safety critical structures, solutions for thermal management solutions (including high-temperature pipework and ducting) and the integration of 3D printed components into the overall assembly.

Our Capabilities

Tube Manipulation

We take flat sheet material and form into tubes with automated seam welding equipment, utilising our electronically controlled CNC Tube Bender.

Hydroforming

We have developed the HydroLite® process, a brand-new, robust means of carrying out hydroforming in vastly reduced lead times and with minimal tooling costs.

Precision TIG Welding

We employ coded specialists in precision TIG, MIG and resistance welding.

Laser and Orbital Welding

We utilise cutting edge, 5-axis laser and orbital welding machines for repeatable, semi-automated production.

Insulating

We offer a variety of insulating techniques to significantly reduce heat transfer to the surrounding areas, which is crucial for high temperature applications.

Non-Destructive Testing

Our in-house Non-Destructive Testing (NDT) facilities allow us to inspect and validate our fabricated structures and check for any defects.

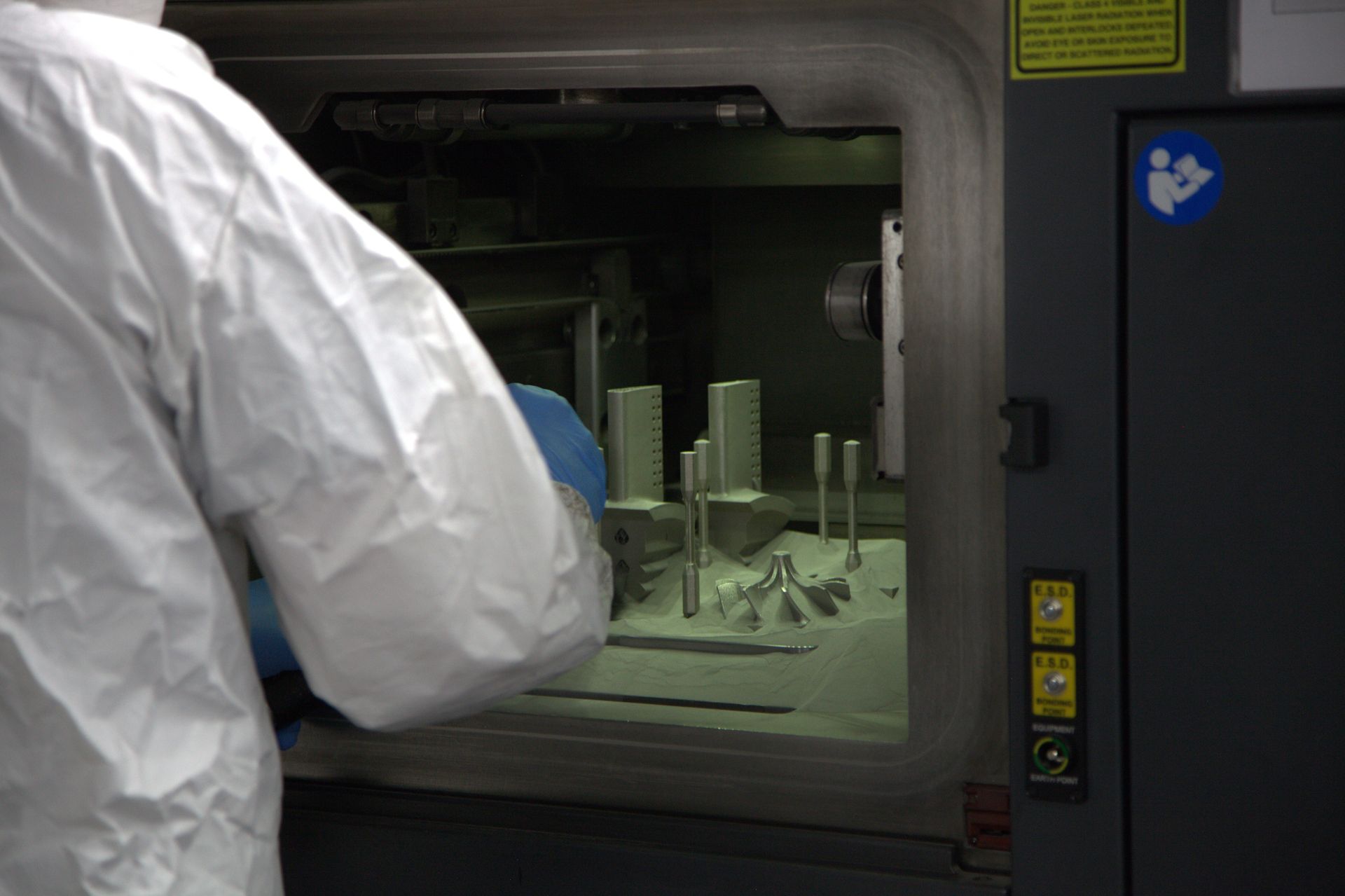

Additive Manufacturing

We can produce DMLS components made from a range of materials including Inconel, Stainless Steel and Aluminium. This allows us to create complex shapes with more flexibility.

Tube Manipulation

We take flat sheet material and form into tubes with automated seam welding equipment, utilising our electronically controlled CNC Tube Bender.

Hydroforming

We have developed the HydroLite® process, a brand-new, robust means of carrying out hydroforming in vastly reduced lead times and with minimal tooling costs.

Insights

Relevant Products

Safety Critical Structures

Find out moreExhaust and Fluid Conveyance Systems

Find out moreThermal Management Solutions

Find out more3D Printed Structures

Find out moreVisit us:

Horizon Technology Park, Stanton Harcourt Rd, Eynsham OX29 4GF

| Polar Technology Management Group Ltd

Website Design by Warpspeed Web