Filament Winding

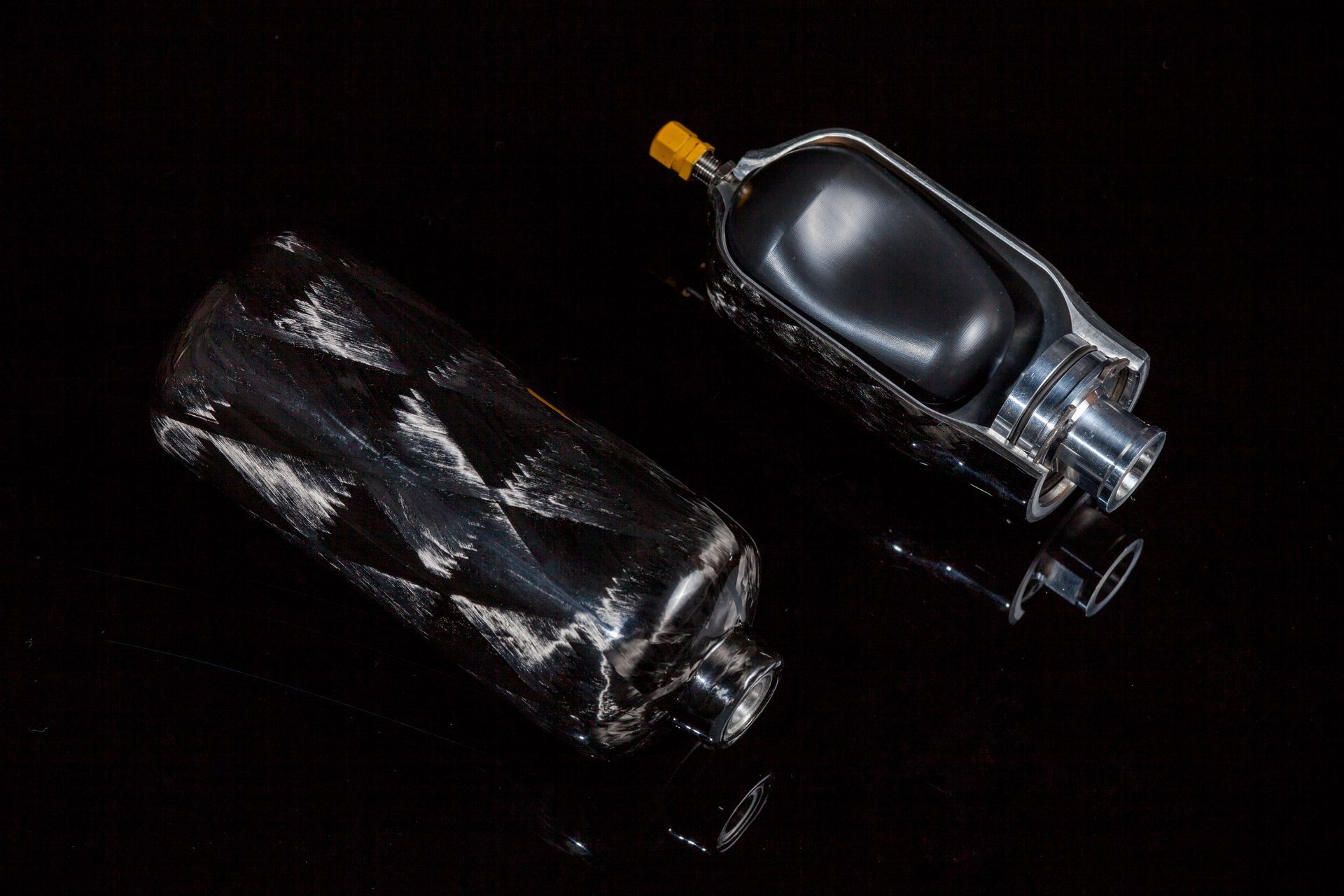

Polar Technology are market leaders in creating filament wound products, with our current portfolio including transmission shafts, pressure vessels and electric motor retention sleeves.

The filament winding process is very flexible, enabling the creation of a wide variety of laminates, with full control over the fibre angles, and can be produced with either a wet wound process or wound with pre-impregnated material in the form of a slit tape or a tow preg.

Our Capabilities

Filament Winding

We have custom-designed, CNC controlled 4-axis filament winding machines with closed loop tension and temperature control.

Autoclaves

We have four on-site autoclaves and several configurations of ovens, suitable for curing wet and pre-preg products.

Measuring

Our composite wound shafts are carefully inspected to ensure the length, outer and inner diameters meet the required specifications.

Pressing & Assembly

Pressing is where our patented mechanical interface is utilised, as the composite structure and metallic end fittings are combined solely by applying pressure at either end.

Balancing

Our balancing equipment analyses if any shaft imbalance may be present, and this is corrected by addition of material through spot welding or removal by machine.

Inspection

In-house we have a comprehensive mechanical test lab which is used to support full product qualification.

Paint Shop

Our specialist, in-house paint shop can provide a variety of high-spec finishes for visual products.

Filament Winding

We have custom-designed, CNC controlled 4-axis filament winding machines with closed loop tension and temperature control.

Autoclaves

We have four on-site autoclaves and several configurations of ovens, suitable for curing wet and pre-preg products.

Insights

Relevant Products

Prop/Drive Shafts

Find out morePressure Vessels and Hydraulic Accumulators

Find out moreElectric Motor Retention Sleeves

Find out moreHydrogen Storage Solutions

Find out moreVisit us:

Horizon Technology Park, Stanton Harcourt Rd, Eynsham OX29 4GF

| Polar Technology Management Group Ltd

Website Design by Warpspeed Web